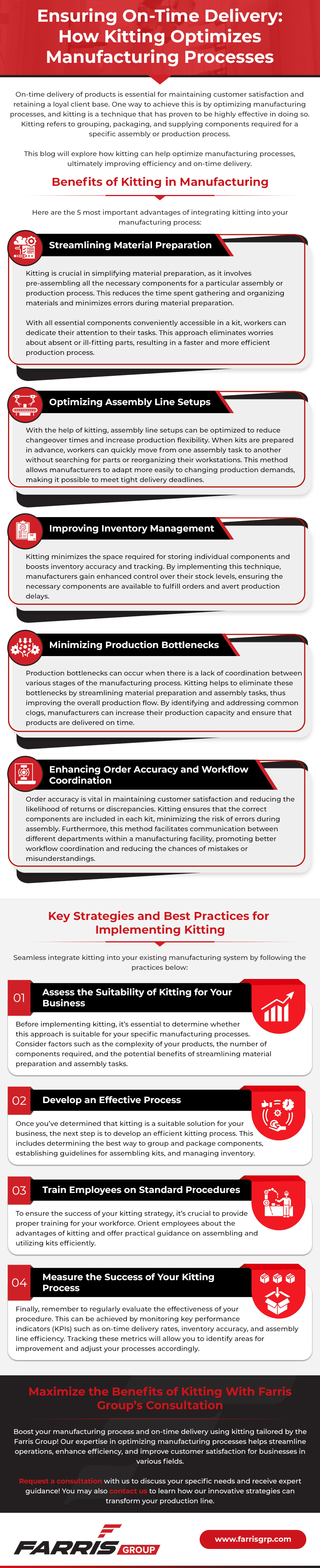

Ensuring On-Time Delivery: How Kitting Optimizes Manufacturing Processes

On-time delivery of products is essential for maintaining customer satisfaction and retaining a loyal client base. One way to achieve this is by optimizing manufacturing processes, and kitting is a technique that has proven to be highly effective in doing so. Kitting refers to grouping, packaging, and supplying components required for a specific assembly or production process.

This blog will explore how kitting can help optimize manufacturing processes, ultimately improving efficiency and on-time delivery.

Benefits of Kitting in Manufacturing

Here are the 5 most important advantages of integrating kitting into your manufacturing process:

1. Streamlining Material Preparation

Kitting is crucial in simplifying material preparation, as it involves pre-assembling all the necessary components for a particular assembly or production process. This reduces the time spent gathering and organizing materials and minimizes errors during material preparation.

With all essential components conveniently accessible in a kit, workers can dedicate their attention to their tasks. This approach eliminates worries about absent or ill-fitting parts, resulting in a faster and more efficient production process.

2. Optimizing Assembly Line Setups

With the help of kitting, assembly line setups can be optimized to reduce changeover times and increase production flexibility. When kits are prepared in advance, workers can quickly move from one assembly task to another without searching for parts or reorganizing their workstations. This method allows manufacturers to adapt more easily to changing production demands, making it possible to meet tight delivery deadlines.

3. Improving Inventory Management

Kitting minimizes the space required for storing individual components and boosts inventory accuracy and tracking. By implementing this technique, manufacturers gain enhanced control over their stock levels, ensuring the necessary components are available to fulfill orders and avert production delays.

4. Minimizing Production Bottlenecks

Production bottlenecks can occur when there is a lack of coordination between various stages of the manufacturing process. Kitting helps to eliminate these bottlenecks by streamlining material preparation and assembly tasks, thus improving the overall production flow. By identifying and addressing common clogs, manufacturers can increase their production capacity and ensure that products are delivered on time.

5. Enhancing Order Accuracy and Workflow Coordination

Order accuracy is vital in maintaining customer satisfaction and reducing the likelihood of returns or discrepancies. Kitting ensures that the correct components are included in each kit, minimizing the risk of errors during assembly. Furthermore, this method facilitates communication between different departments within a manufacturing facility, promoting better workflow coordination and reducing the chances of mistakes or misunderstandings.

Key Strategies and Best Practices for Implementing Kitting

Seamless integrate kitting into your existing manufacturing system by following the practices below:

Assess the Suitability of Kitting for Your Business

Before implementing kitting, it’s essential to determine whether this approach is suitable for your specific manufacturing processes. Consider factors such as the complexity of your products, the number of components required, and the potential benefits of streamlining material preparation and assembly tasks.

Develop an Effective Process

Once you’ve determined that kitting is a suitable solution for your business, the next step is to develop an efficient kitting process. This includes determining the best way to group and package components, establishing guidelines for assembling kits, and managing inventory.

Train Employees on Standard Procedures

To ensure the success of your kitting strategy, it’s crucial to provide proper training for your workforce. Orient employees about the advantages of kitting and offer practical guidance on assembling and utilizing kits efficiently.

Measure the Success of Your Kitting Process

Finally, remember to regularly evaluate the effectiveness of your procedure. This can be achieved by monitoring key performance indicators (KPIs) such as on-time delivery rates, inventory accuracy, and assembly line efficiency. Tracking these metrics will allow you to identify areas for improvement and adjust your processes accordingly.

Maximize the Benefits of Kitting With Farris Consultation

Boost your manufacturing process and on-time delivery using kitting tailored by the Farris! Our expertise in optimizing manufacturing processes helps streamline operations, enhance efficiency, and improve customer satisfaction for businesses in various fields.

Request a consultation with us to discuss your specific needs and receive expert guidance! You may also contact us to learn how our innovative strategies can transform your production line.